UNIFLOW HOT MELT DRUM UNLOADER

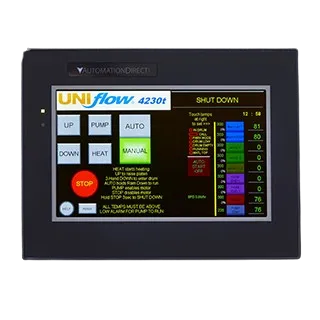

Uniflow Model 4230

The Uniflow Model 4230 Hot Melt Drum Unloader is a high-performance, cost-effective solution designed for the rapid and efficient application of hot melt adhesives in a wide range of industrial processes. This machine is particularly beneficial for industries requiring high output and reliable performance.

KEY FEATURES

PERFORMANCE ADVANTAGES

at least

40%

faster

MAXIMUM OUTPUT

GUARANTEED PUMP RATES AT LEAST 40% FASTER THAN COMPETING MACHINES

square

4663

inches

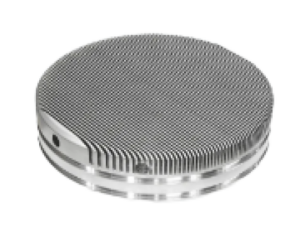

OPTIMIZED HEAT TRANSFER

4,663 SQUARE INCHES OF HEATED PLATEN SURFACE AREA PROVIDES SUPERIOR HEAT TRANSFER

up to

95%

less

MINIMUM MATERIAL WASTE

LEAVES ONLY 2 LBS IN THE DRUM – THE COMPETITION LEAVES 20-40 LBS WASTED!

30+

years

LONG-LASTING & RELIABLE

MANY UNIFLOW SYSTEMS HAVE BEEN RUNNING DAILY IN PRODUCTION FOR OVER 30 YEARS!

PUMP RATES

| Hot Melt Material | Primarily Used For | Uniflow 4230 |

|---|---|---|

| Polyurethane Reactive (PUR) | Furniture, Flooring, RVs, Woodworking, Bookbinding | 150 to 1,500 PPH |

| Pressure-Sensitive Adhesive (PSA) | Tape, Labels | 400 to 900 PPH |

| Amorphous Polyolefin (APO) | Packaging, Nonwovens | 400 to 600 PPH |

| Ethylene-Vinyl Acetate (EVA) | Paper, Packaging, and Assembly | 400 to 900 PPH |

| Butyl Rubber | Insulated Glass | 150 to 400 PPH |

| Acrylic | Wood, Glass, Metal, and Waterproof Items | 400 to 600 PPH |

| UV Curable | Glass, Plastic, or Architectural Bonding | 500 to 900 PPH |

| Mastic | Underground Cable | 400 PPH |

OPTIONS

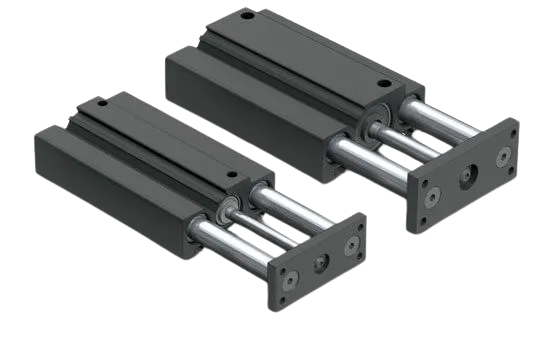

TANDEM OPTION FOR CONTINUOUS OUTPUT

Uniflow 4230 drum unloaders can be configured into a continuous output system; automatically switching so material flow to the line is never interrupted. We can configure the system to operate as two stand-alone units, each with a hose running to the production line, or both machines can feed a 2-in, 1-out heated manifold..

INDUSTRY APPLICATIONS

The high-performance, cost-effective Uniflow 4230 is engineered for the rapid and efficient application of hot melt adhesives in a wide range of industrial processes. This machine is particularly beneficial for industries requiring high output and reliable performance.

CASE STUDIES & VIDEOS

See how Uniflow’s Model 4230 improves efficiency and production across industries. Our case studies and videos offer real-world examples, customer testimonials, and demonstrations of our equipment in action.